The ATHEX process allows the thickness of the tube wall to be adapted to this decreasing pressure load, allowing material savings of up to 25% while maintaining static integrity. In addition to a significantly better environmental balance, this results in clear cost advantages due to reduced material costs and easier assembly due to the lower weight.

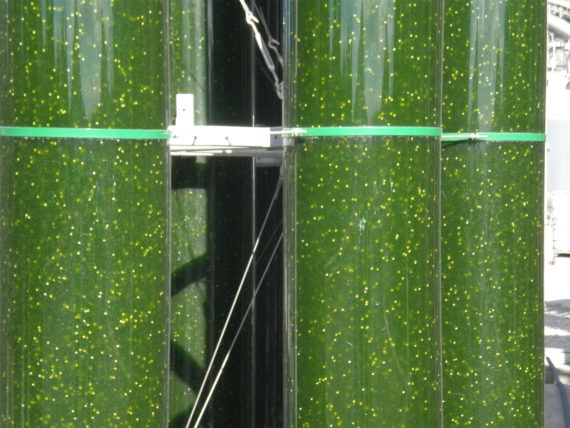

In recent years, ATHEX has acquired extensive manufacturing expertise through the supply of acrylic tubes for bioreactors and also has the appropriate equipment to produce the tubes.