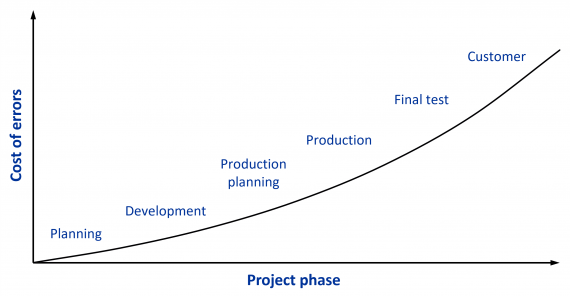

Through our 20 years of experience, we have built up extensive and in-depth knowledge in the field of material selection/modification as well as extrusion. We see ourselves not only as a supplier, but also as a partner. This means that we can advise and support you in the selection of materials and the design of the product from a production point of view. Early assistance from us can avoid a costly revision later in your project phase.

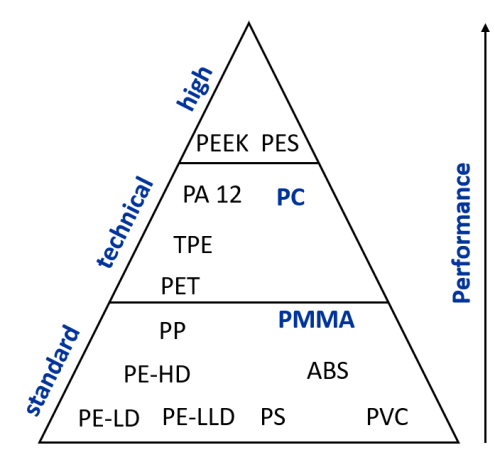

For the extrusion of our tubes and profiles, we not only draw on all our experience and use state-of-the-art equipment, we also use plastics from the top segment of standard and engineering plastics.

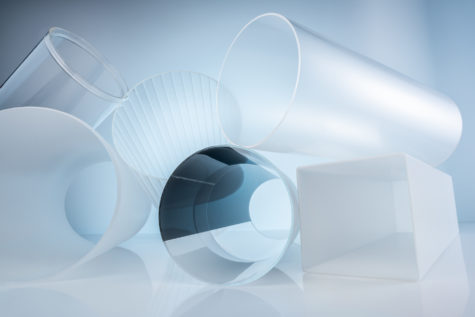

We focus on the requirements of your product in terms of its optical and mechanical properties.

The foundation stone for the quality we can achieve is already laid in the selection of our tube material suppliers for polycarbonates (PC) and polymethyl methacrylates (PMMA). That is why we only source our materials from well-known, globally operating premium manufacturers. This forms the basis for the high and consistent quality of our plastic tubes and plastic profiles.

To ensure that our products meet your requirements, we offer various blends (material mixtures). This enables us to increase the performance of the base material (PC/PMMA) and adapt it to your needs.

The versatility of our tubes and profiles allows our customers to open up new fields of application again and again, whether in the lighting industry, shop and trade fair construction, in algae cultivation, in pneumatic tube systems or in the many other possible applications. In order to meet the associated requirements for the PC or PMMA, we offer individual and application-specific materials for you. In order to obtain a combination of different properties, our basic material PC/PMMA is combined with other materials to form a blend.

This allows us to adapt our tubes and profiles to your areas of application, whether you require optical, mechanical or even hygienic properties.

Matched to the required lighting applications in the lighting industry, we extrude the tubes and profile with a diffuse (satin), opal (white) or transparent appearance. The supreme discipline here lies with the transparent tubes. In addition, we have developed an LED blend especially for LED luminaires which, despite the very high light output, allows hardly any or no light points to be detected, depending on the requirements. Individual colours or even fluorescent tubes are also no problem for us – feel free to contact us.

In addition to an increase in impact strength for applications subject to particularly high mechanical stress, such as outdoor lighting in public areas, it is also possible to implement hygienic and antibacterial protection for applications in the medical environment.